Commercial Stainless Steel Sink Solutions Suppliers Love Most

What makes a commercial stainless steel sink a favorite among knowledgeable suppliers? While many factors matter, suppliers consistently prioritize partners who deliver unwavering quality, functional design, and hassle-free compliance.

Xinhe Stainless Steel Products Co., Ltd. stands out in this regard by combining custom manufacturing capabilities with a rigorous focus on innovation and durability. For suppliers, the evaluation hinges on a few critical pillars that directly impact their clients’ success:

- Material Integrity: Ensures long-term durability and meets strict hygiene standards.

- Practical Design: Features that simplify cleaning, maintenance, and daily operation.

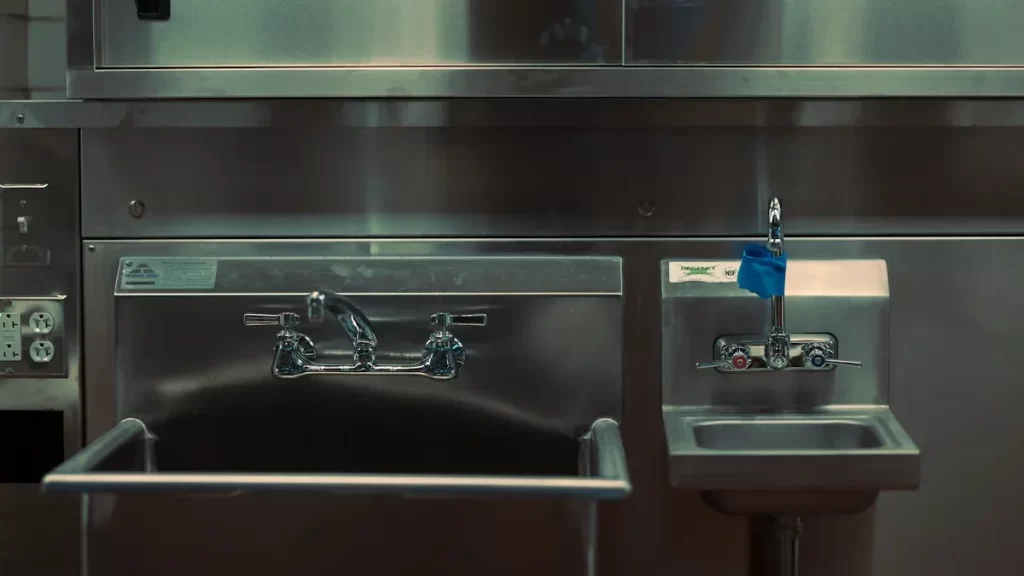

- Regulatory Compliance: like NSF certification, which safeguards end-users and simplifies the specification process.

These things help buyers pick sinks that last long, stay clean, and follow the rules.

Commercial Stainless Steel Sink Comparison

Key Specs and Supplier Ratings

People who buy sinks for businesses look at important details. The table below shows what matters most to suppliers:

| Specification | Description |

|---|---|

| Gauge | Lower numbers like 16 or 18 mean the steel is thicker and stronger. |

| Finish | Brushed or satin finishes hide marks and are easier to keep clean. |

| Drainage System | Sloped basins help water drain quickly and keep sinks clean. |

| Noise Reduction | Pads or coatings help make the kitchen quieter. |

| Installation Types | Drop-in and undermount styles change how simple it is to put in the sink. |

| Compliance | 304 stainless steel follows health and safety rules. |

A good warranty is also very important for peace of mind.

Finding Trusted Suppliers

People who buy for companies want these things from a supplier:

- Clear prices with no extra costs

- Many products to pick from

- NSF-certified items for safety

- Friendly customer service

- Good warranties and shipping across the country

- Help after you buy

Xinhe Stainless Steel Products Co., Ltd. is special because it makes custom sinks and cares about quality. If you need a custom sink or special order, you can ask Xinhe for help.

Supplier Insights: What to Look For

1. Durability and Material Quality

Suppliers care a lot about how long sinks last. They check the steel’s type and thickness. Thicker steel, like 16 gauge, is stronger and handles tough jobs. Thinner steel, like 18 gauge, costs less and works for lighter jobs.

| Gauge Type | Durability | Cost | Recommended Use |

|---|---|---|---|

| 16 Gauge | Higher strength, more resistant to dents | More expensive | Heavy-duty use, high-end options |

| 18 Gauge | Slightly less robust, economical choice | Less expensive | Most residential kitchen sinks, general use |

Suppliers also look at the steel grade. Grades with more chromium and nickel, like 304 or 316, fight off rust and stains. This is important in kitchens and wet places.

Xinhe is a good example because they alway focus on quality and new ideas. Their R&D team tries to make sinks stronger and better looking.

2. Design, Functionality, and Compliance

Suppliers want sinks that follow health and safety rules. They like sinks that are easy to clean and stop germs from spreading. A good commercial stainless steel sink should have smooth corners, sloped basins, and drains that work well.

| Design Feature/Compliance Standard | Description |

|---|---|

| Stainless Steel Grade | 304 stainless steel is best because it is strong and does not rust easily |

| Sink Setup | Needs hot and cold water, good drainage, and must follow health codes |

| NSF Certification | Shows the sink passes tough public health rules |

Suppliers also check for certifications like NSF, cUPC, CE, and ISO 9001. These show the sink is safe and good quality. Xinhe can make custom sinks to help buyers meet local rules and special needs.

3. Installation and Maintenance

Putting in a commercial stainless steel sink can be hard. Common problems are with the pipes, supporting the sink’s weight, and air flow.

| Challenge | Explanation |

|---|---|

| Plumbing | Licensed plumbers make sure pipes are right and follow the rules |

| Weight Support | Good anchors stop accidents, especially for wall sinks |

| Air Flow | Airflow keeps water from building up and keeps things safe |

| Health and Safety Standards | Following rules stops fines and keeps work going well |

To keep a sink in good shape, clean it with mild soap, dry it after use, and don’t use harsh chemicals. Check for leaks and clogs often to help the sink last longer.

Solutions to Common Supplier Issues

Challenges in Sourcing and Procurement

The table below shows some common problems and what they mean:

| Challenge | Explanation |

|---|---|

| Negotiation Complexities | Getting a good price needs strong skills and clear deals. |

| Communication Barriers | Language and culture can make talking hard in global business. |

| Minimum Order Quantities (MOQ) | Suppliers set MOQs to pay for making sinks, but buyers may want less. |

| Lead Times | Making and shipping sinks can take a long time, so planning is needed. |

| Quality Control Issues | Keeping the same quality for every order helps protect the brand. |

Suppliers use different ways to fix supply chain problems. They pick more than one supplier so they do not depend on just one. They build good relationships to get help faster when there are problems. They use technology to track orders and manage risks better.

Suppliers also fix raw material shortages by making long contracts and finding more sources. They work with shipping partners to solve transport issues. They learn about trade rules to lower risks.

Customization and OEM/ODM Requests

Many buyers want custom sinks for their business projects. Suppliers get requests for:

| Customization Type | Description |

|---|---|

| Handmade Stainless Steel Sinks | These sinks let buyers choose special designs for tough jobs. |

| Mold-Based Production | Molds help make many sinks at once for big orders. |

| Material Selection | Buyers can pick different steel grades and thicknesses like 304 or 316. |

| Surface Treatment | Sinks can have finishes like polish, nano-coating, or PVD in many colors. |

| Quality Inspection | Tests check if sinks are strong and do not leak to meet ISO rules. |

| Delivery Time | Custom sinks take about 4-8 weeks, depending on size and design. |

Xinhe Stainless Steel Products Co., Ltd. is special because it offers full custom sinks. It uses new technology and has a smart R&D team. Their engineers help buyers make sinks that fit their needs.

Installation and After-Sales Support

Suppliers help buyers put in sinks and give support after buying. They send replacement parts if needed. They give tips for daily care. They answer questions about installing and using sinks.

To stop installation problems, suppliers say to remove old sealant and put on new sealant right. Wait for sealant to dry before using the sink. Check and tighten all parts. Plan for good plumbing, support, and air flow. Look for cracks or leaks and fix small problems early.

Quality Assurance and Certifications

Quality checks make sure every sink meets high standards. Important things to look for are:

| Criteria | Importance | Key Indicators |

|---|---|---|

| ISO Certification Validity | Shows the sink follows world rules | Real certificates like ISO 9001, ISO 14001, NSF |

| Material Quality | Makes sure sinks last long and stay clean | Use steel grades like 304 or 316 |

| Quality Control Processes | Keeps products the same every time | Careful checks and inspections |

Suppliers like Xinhe have certificates such as ISO9001, cUPC, CE, and Watermark. These show they care about making good and reliable sinks.

Best Sinks for Different Commercial Settings

Foodservice and Restaurants

Picking the right commercial stainless steel sink helps kitchens work better. It also helps restaurants follow health rules. Many restaurants use triple-compartment sinks. These sinks are for washing, rinsing, and sanitizing dishes. Hand sinks and prep sinks are kept separate. This stops germs from spreading. Most suppliers say to use sinks made from 304-grade stainless steel. This material does not rust or corrode. That is important in busy kitchens. Sinks with 16 or 18-gauge thickness are stronger. They last longer and can handle lots of use. Drainboards built into the sink help staff work faster. They also keep the kitchen clean.

Key features for foodservice:

- Triple-compartment design for dishwashing

- Separate hand and prep sinks

- 304-grade stainless steel for durability

- 16 or 18-gauge thickness

- Integrated drainboards

Hospitality and Hotels

Hotels need sinks that can be used a lot. They must hold heavy pots and pans. Strong sinks are needed for busy kitchens and staff rooms. Cleanliness is very important in hotels. They must follow health and safety rules. Many sinks have pads that make them quieter. These pads lower noise from dishes and water. This helps keep the kitchen and staff areas calm and clean.

Features valued in hospitality:

- Strong construction for frequent use

- Easy-to-clean surfaces

- Sound-dampening pads for noise reduction

Healthcare and Public Facilities

Healthcare places and public buildings need sinks that help stop germs. Sinks with smooth surfaces and rounded corners are easier to clean. They must meet health standards. Many need certifications like NSF or ISO. Stainless steel sinks do not let bacteria grow. They also resist chemicals. This makes them good for hospitals and public places.

| Setting | Important Features |

|---|---|

| Healthcare | Smooth surfaces, certifications |

| Public Facility | Easy cleaning, rust resistance |

Specialty and Custom Applications

Some businesses need special sinks for their work. Pet care centers, labs, and outdoor places ask for different shapes and sizes. Suppliers like Xinhe can make custom sinks for these needs. Custom sinks can have deep basins, special coatings, or different drainage systems.

Tip: Buyers should talk to suppliers about what they need. This helps make sure the sink is right for the job.

Tips for Buying Commercial Stainless Steel Sinks

Questions to Ask Suppliers

- What grade and gauge does the sink have?

- Does the sink meet health and safety rules like NSF or ISO?

- How long does delivery take?

- Can you make custom sizes or add features?

- What does the warranty cover and how long is it?

- Do you give guides for installation and help after buying?

Common Pitfalls to Avoid

- Not reading the warranty before buying.

- Not knowing what the warranty covers or how long it lasts.

- Doing things that can cancel the warranty, like using the sink wrong.

- Forgetting to get help with installation.

- Not checking for certifications that show quality and safety.

- Picking the wrong size or type of sink for the space.

Tip: Always check the warranty and ask for clear instructions. This helps you avoid problems later.

Finding a Trusted Supplier

Look for a supplier that:

- Has clear prices.

- Sells products with certifications (like NSF).

- Has good customer service.

- Offers a strong warranty and can ship to you.

FAQ

What are the most important factors when choosing a commercial stainless steel sink?

Buyers need to check if the material is good. They should see how thick the steel is. Certifications are important too. Look for sinks that are easy to clean. Make sure the sink lasts a long time. It should follow health rules.

How do suppliers handle custom sink requests?

Suppliers first learn what the buyer wants. They show different designs and materials. Engineers make samples or drawings. Production starts after the buyer says yes.

What certifications should a commercial stainless steel sink have?

NSF certification means the sink is safe for health. ISO 9001 shows the company checks quality. cUPC and CE prove the sink follows safety rules.

What are common installation challenges for commercial sinks?

Installers sometimes have trouble with plumbing. They need to make sure the sink is held up well. Good airflow is needed too. They must follow local rules and use strong anchors.

How can buyers ensure long-term durability and easy maintenance?

Clean the sink with gentle soap and a soft cloth. Dry the sink after you use it. Check for leaks or clogs often. Do not use strong chemicals.