How to Find a Durable Wall Hung Slop Sink for Heavy Use

Did you know that over 30% of commercial sinks break early? This happens because they are not installed well or use weak material. Those in charge of maintenance have big problems when a wall hung slop sink cannot take heavy use. Many people pick stainless steel because it is strong and easy to clean. Xinhe has many years of experience making stainless steel solutions for B2B clients. Choosing the right sink means you will fix it less and spend less money later.

Wall Hung Slop Sink Durability Factors

What Makes a Sink Durable

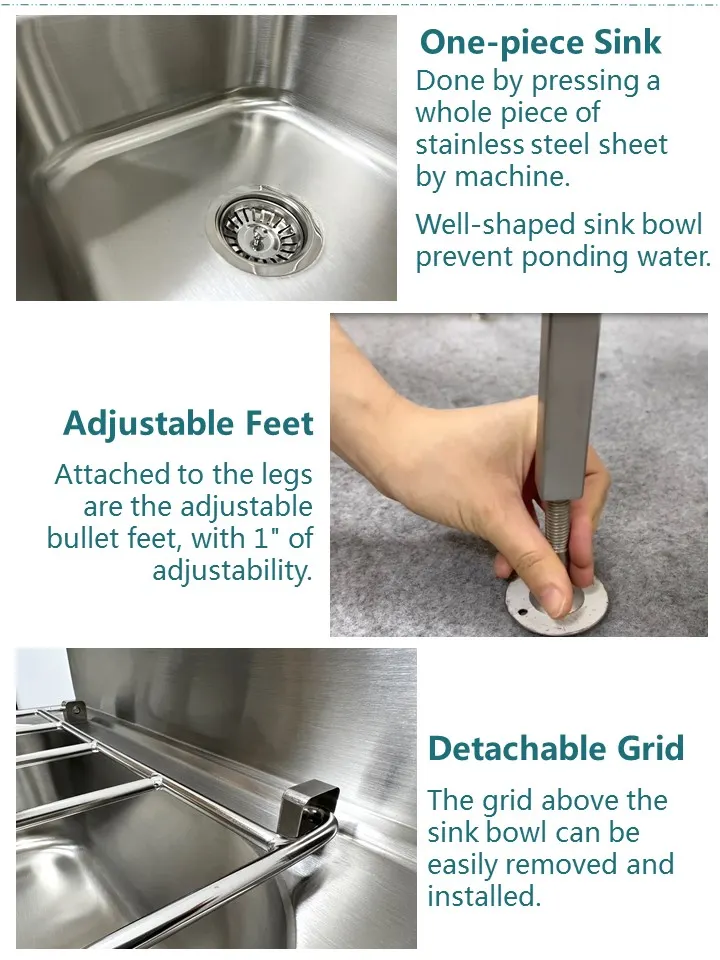

A strong wall hung slop sink can handle lots of use. Decision-makers want sinks that last a long time. Replacing sinks often costs more money and time. The main things to look for are tough materials, good mounting hardware, and smart design. Stainless steel is a top pick because it does not rust or break easily. Xinhe’s team uses high-quality stainless steel and special welding to make sinks stronger.

Here’s a quick look at what matters most:

| Factor | Why It Matters | How to Ensure Safety |

|---|---|---|

| Wall Strength | Weak walls may not support the sink, causing accidents. | Use reinforced concrete or walls with proper framing. |

| Mounting Hardware | Poor brackets or bolts can fail over time. | Choose heavy-duty brackets and secure all hardware. |

| Sink Material | Heavy materials need strong support. | Pick materials that balance weight and durability. |

| Weight Capacity | Too much weight strains the mounting system. | Follow manufacturer’s weight limits. |

| Professional Installation | Incorrect installation leads to wobbly sinks or accidents. | Hire certified installers for best results. |

Common Failure Points

Wall hung slop sinks can break if they are not mounted well. In daily operation and maintenance, common problems like loose brackets, cracked walls, or leaks. These problems can stop work and cost a lot to fix. Here are some common trouble spots:

- Brackets that bend or break under heavy loads

- Walls that crack or crumble due to poor support

- Sink basins that rust or corrode from harsh chemicals

- Drainage systems that clog or leak

Tip: Check your sink often to find problems early. Facility teams should look at the mounting hardware and wall strength every few months.

Key Features for Reliability

Good wall hung slop sinks have important features. Purchasing and operations parties look for these when picking new sinks. The right features make cleaning easier and help the sink last longer.

| Feature | Description | Benefit |

|---|---|---|

| Durability | Made from strong materials like stainless steel or cast iron. | Handles tough cleaning tasks |

| Space Efficiency | Wall-mounted design saves floor space in busy utility rooms. | Maximizes usable area |

| Functionality | Drainboards and deep basins add convenience for cleaning staff. | Improves usability and workflow |

This type of user like sinks with deep basins and smooth surfaces. Xinhe’s sinks have strong mounting brackets and smooth welds to stop leaks. These features help buyers follow rules and save money over time.

A wall hung slop sink with good design and materials can work well in schools, hospitals, and factories. Before purchasing, be sure to check for strong mounting hardware, reinforced walls, and easy-to-clean surfaces before buying.

Material Choices for Heavy Use

Stainless Steel Advantages

In busy locations, stainless steel is the first choice for heavy use. Stainless steel is popular for many reasons:

- It is simple to clean and stops germs. The smooth surface does not let bacteria grow. Staff can clean it fast with soap and water.

- It lasts a long time. Stainless steel does not rust, chip, or crack. It works well in hospitals, schools, and food factories.

- It needs little care. The surface stays clean with regular cleaning. There is no need to spend much time fixing or scrubbing the sink.

- It helps keep things hygienic. Clean sinks are important in labs and kitchens. Stainless steel helps keep these places safe.

The operations side likes stainless steel because it saves time. It also lowers repair costs. This helps meet health rules.

Comparing Other Materials

Some sinks use ceramic, composite, or bio-based resin. These materials have good points, but they do not match stainless steel for heavy use.

- Ceramic sinks break more easily. They chip and crack, so teams must check and clean them often.

- Composite sinks are hard to recycle. Many end up in landfills, which hurts the environment.

- Bio-based resin sinks are easier to recycle now, but they still need more work.

Here is a quick look at how these materials compare:

| Material Type | Durability | Maintenance Needs | Environmental Impact |

|---|---|---|---|

| Stainless Steel | High | Low | ~90% recyclable |

| Ceramic | Medium | High | Often ends up in landfills |

| Composite (Quartz/Stone) | Medium | Medium | Hard to recycle |

| Bio-based Resin | Improving | Medium | Getting more eco-friendly |

From practical use, stainless steel sinks last longer. And cost less to take care of.

Impact on Maintenance

The material you choose changes how often teams clean or repair a wall hung slop sink. Stainless steel sinks need less work. Staff can clean them fast, and they do not break often. Ceramic sinks need more checks and deep cleaning. Over time, ceramic sinks cost more to keep up than stainless steel.

Tip: Facility teams should pick materials that save time and money. Stainless steel sinks help lower costs and keep work areas safe.

Decision-makers looking for high-use sinks pick stainless steel. This means fewer problems and better results.

Installation and Mounting Essentials

Preparing for Installation

- Pick the right spot for the sink. Make sure it follows plumbing rules and is close to water lines.

- Get all the tools and materials you need before you start.

- Take the sink out of the box and check for damage. Measure everything again to be sure.

- Read the instructions from the manufacturer. Each sink might have special steps.

- Get the wall ready. Make it stronger if needed so it can hold the sink.

- Put in the mounting hardware. Use strong brackets to keep it safe.

- Add taps and other fixtures.

- Connect the water lines and drainage system.

- Make sure the sink is level and tighten it well.

- Test the sink. Check for leaks and see if it feels steady.

Tip: Always follow plumbing codes and safety rules when you install a sink.

Mounting Methods

There are different ways to mount sinks in many places. Some designs work better in small rooms or busy areas. These features help save space and make the sink more useful:

| Feature | Description |

|---|---|

| Integrated Towel Bar | Lets you hang towels without making a mess. |

| Floating Design | Makes the room look bigger, good for small spaces. |

| Multi-Basin Compatibility | Fits many sink shapes, so you have more choices. |

| Storage Shelf | Gives you a place to keep things you need. |

| Modern Aesthetic | Looks clean and simple, great for modern rooms. |

| Ideal Applications | Works well in small bathrooms, public restrooms, and hotels. |

Floating sinks is popular in small spaces. Shelves and towel bars help keep things neat and close by.

Compliance and Safety

Safety and rules are important in every building. Contractors must follow codes and health standards. Strong mounting stops the sink from falling. Good sealing keeps water from leaking and causing damage. Checking the sink often helps find problems early.

- Use certified installers for the best job.

- Make sure all hardware follows local codes.

- Check that the sink height is right for everyone.

- Look at the sink and wall often for damage.

A well-installed wall hung slop sink keeps people safe and work areas clean. Following these steps can help stop expensive repairs and lost time.

Maintenance for Long-Term Performance

Cleaning Best Practices

Regular cleaning is key to keeping wall hung slop sinks working well. Stainless steel surfaces clean up fast, but every sink needs a routine. Staff should use mild soap and hot water. It is recommended to use wipe down the basin with a soft cloth to remove grime. Hot water helps break down grease and dirt. It should be run hot water through the sink a few times each week. This step keeps pipes clear and helps prevent buildup.

Tip: Avoid harsh chemicals like bleach. Bleach can damage drains and pipes. Instead, use bio-enzymatic cleaners or drain sanitizers for sinks that handle food or beverages.

Preventing Issues

Preventative maintenance stops problems before they start. A checklist is often set up for maintenance work. Here are some smart steps:

- Make sure sinks always have hot water and soap.

- Clean sink drains every day to keep fruit flies and mold away.

- Cover drains with rocks glasses or plastic wrap to deter pests.

- Outfit sinks with fine mesh colanders. These catch debris and protect pipes.

- Schedule plumbing checks twice a year. Regular inspections help spot leaks or weak brackets early.

A simple routine saves time and money. Strictly executing these steps can result in fewer clogs and less downtime.

Repair or Replace

Sometimes, even the best-maintained sink needs attention. One must be alert for signs that a wall hung slop sink needs repair or replacement. Common warning signs include:

- Faucet dripping or leaking

- Low water pressure or interrupted flow

- Drain clogged

Once these problems are noticed, act fast. Small repairs, like fixing a leaky faucet, keep the sink working longer. If the sink feels loose or the wall shows cracks, replacement may be safer. Quick action helps keep work areas clean and safe.

Note: Regular checks and fast repairs help avoid bigger problems. Facility teams who stay alert keep their wall hung slop sinks in top shape.

Picking a strong wall hung slop sink means using tough materials. Good construction and careful setup are important too. Xinhe helps business clients with sinks made for small spaces. Their custom sinks make work easier and fit special needs. These sinks use Grade 304 stainless steel. This metal does not rust and is simple to clean. In the long run, this can save money over time and keep things cleaner.

Need help? Contact Xinhe or check their website for custom stainless steel sinks.

- Use space well and work faster

- Make staff feel safe and comfortable

- Follow industry rules without trouble

FAQ

What makes a wall hung slop sink suitable for heavy use?

A wall hung slop sink for heavy use needs strong stainless steel, sturdy mounting brackets, and a deep basin. These features help the sink handle frequent cleaning and heavy buckets without bending or leaking.

How often should facility teams inspect wall hung slop sinks?

It is recommended to check wall hung slop sinks every few months. They should look for loose brackets, leaks, or signs of rust. Regular inspections help catch small issues before they become big problems.

Can a wall hung slop sink fit in small utility rooms?

Yes, many wall hung slop sinks have a compact design. They save floor space and fit well in tight areas like janitor closets, school bathrooms, or hospital utility rooms.

What cleaning products work best for stainless steel slop sinks?

Mild soap and warm water work best for daily cleaning. Harsh chemicals should be avoid. For tough stains, a soft cloth and a little baking soda can help keep the sink shiny.

Are wall hung slop sinks easy to install?

Most wall hung slop sinks come with clear instructions. Contractors need to use strong walls and heavy-duty brackets. Professional installation helps ensure the sink stays safe and secure.