Prison Toilet Sink Combo: The New Standard in Cell Design

In the high-stakes world of correctional architecture, every design choice is a matter of safety, economics, and long-term durability. Perhaps no single fixture embodies these priorities more than the prison toilet sink combo. While it might look like a simple space-saver, this unit actually engineers a sophisticated solution for some of the most difficult challenges in detention management. This guide explores why this integrated design has become the global standard for modern correctional facilities, providing a deep dive into the engineering, operational, and financial logic behind its widespread adoption.

The Strategic Importance of Integrated Cell Fixtures

The environment inside a correctional facility is inherently adversarial. Security experts must evaluate every object within an inmate’s reach for its potential to be weaponized, dismantled, or used as a tool for self-harm. In this context, the traditional bathroom layout—with separate porcelain toilets, wall-mounted sinks, and exposed piping—creates a significant security liability.

The move toward the prison toilet sink combo represents a shift toward “defensive engineering.” By merging the water closet and the lavatory into a single, seamless, and indestructible unit, facility managers can eliminate many of the vulnerabilities inherent in standard plumbing. This integration is not merely a convenience; it is a foundational element of modern security protocol.

1. Security Engineering: Neutralizing the Adversarial Environment

In any prison, the primary objective of facility design is the mitigation of risk. The prison toilet sink combo functions as a “passive security” asset, meaning it enhances safety through its physical form without requiring active intervention from staff.

Anti-Ligature and Suicide-Resistant Design

One of the most critical challenges in detention health is the prevention of self-harm. Standard plumbing fixtures often have multiple “anchor points”—protruding faucets, exposed piping, or gaps between the fixture and the wall—where inmates could attach a cord, cloth, or wire.

Manufacturers design modern prison toilet sink combo units using anti-ligature principles.This involves:

- Rounded Contours: Every edge is radiused to ensure there are no sharp corners.

- Seamless Transitions: The sink bowl is integrally welded to the toilet body, leaving no gaps.

- Sloped Surfaces: Horizontal surfaces are sloped to prevent anything from being hung or looped over them.

- Internal Bubblers: Instead of a traditional faucet that can be gripped or broken, these units use recessed bubblers that are flush with the stainless steel surface.

Tamper-Proof and Vandal-Resistant Construction

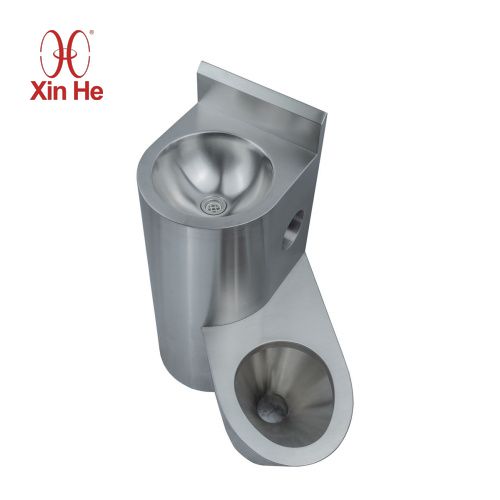

Standard porcelain shatters easily. A broken toilet provides hundreds of razor-sharp shards that inmates can use as knives or scalpels. For this reason, manufacturers construct the prison toilet sink combo from heavy-gauge, type 304 or 316 stainless steel.

Stainless steel is ductile; it might dent under extreme impact, but it will not shatter. Furthermore, installers typically “front-mount” or “chase-mount” these units using tamper-resistant security bolts. Understanding why prison facilities choose stainless steel toilets over porcelain is essential for anyone involved in high-security procurement, as the safety implications are immediate and profound.

Contraband Control and Cavity Elimination

Inmates are creative in finding places to hide illicit items, such as drugs, weapons, or communication devices. Traditional toilets have hollow bases and exposed traps that serve as perfect hiding spots.

The fully enclosed “skirt” of a high-quality prison toilet sink combo eliminates these cavities. Security-grade sealant seals the entire unit against the wall and floor, ensuring that there are no accessible voids. This design simplifies cell shakedowns, allowing staff to quickly verify that inmates have hidden no contraband in or around the plumbing fixtures.

2. Architectural Efficiency: Optimizing the 6×8 Footprint

Prison construction is incredibly expensive, often costing hundreds of dollars per square foot due to reinforced concrete, specialized electronics, and security barriers. Architects must therefore maximize the utility of every square inch.

The Compact Cell Footprint

The American Correctional Association (ACA) and other international bodies provide strict guidelines for cell size, often recommending a minimum of 70 square feet for a single-occupancy cell. In a typical 6×8 foot cell, every inch of floor space is vital for inmate movement and psychological well-being.

By consolidating the toilet and sink into one vertical unit, the prison toilet sink combo significantly reduces the fixture’s footprint. This allows for:

- Increased “Clear” Floor Space: More room for the inmate to move, reducing the feeling of claustrophobia.

- Simplified Layouts: Architects can place the fixture in a corner or against a shared utility wall, streamlining the overall building design.

One of the most significant architectural benefits of the prison toilet sink combo is its compatibility with the “plumbing chase” design. A plumbing chase is a narrow service corridor located behind the cell wall that houses all water supply lines, waste pipes, and electrical conduits.

Most prison toilet sink combo units are designed for rear-access installation. This means:

- No Staff-Inmate Interaction During Maintenance: A plumber can service the flush valve or fix a leak from the chase without ever entering the cell. This maintains a clear security boundary and prevents the need for risky cell extractions.

- Protection of Components: All valves, sensors, and pipes are located in the chase, completely out of reach of the inmate. This prevents intentional flooding or tampering with water supplies.

Experienced consultants often emphasize what you should know about prison toilet construction when planning these chases to ensure long-term maintenance efficiency.

3. Advanced Water Management and Flood Prevention

Water is frequently used as a tool for disruption in correctional environments. Inmates may attempt to flood a cell block by blocking the toilet and holding down the flush button. To counter this, the prison toilet sink combo integrates sophisticated control systems.

Electronic Metering and Lockout Controls

Modern units often bypass the traditional manual flush valve in favor of electronic solenoid valves. These systems allow facility managers to program specific usage parameters:

- Flush Limiting: The system can be set to allow only two flushes every 30 minutes. If an inmate exceeds this, the valve locks out.

- Timed Sink Flow: Sinks are activated by a push-button that delivers a precise amount of water (e.g., 10 seconds), preventing the tap from being left on.

- Master Shut-off: During a riot or emergency, staff can shut off water to an entire wing or a specific cell from a central computer.

High-Efficiency and Environmental Stewardship

Operational costs are a major concern for B2B procurement in the public sector. High-efficiency prison toilet sink combo units typically utilize 1.28 gallons per flush (GPF) or even 1.0 GPF. Over the course of a year, in a facility with 1,000 inmates, these savings represent millions of gallons of water and tens of thousands of dollars in utility costs.

| Water Control Feature | Security Benefit | Operational Benefit |

|---|---|---|

| Electronic Lockout | Prevents intentional cell flooding | Reduces water waste by up to 40% |

| Timed Flow Bubbler | Prevents tap-running disruptions | Lowers sewage and utility costs |

| Vacuum Flush Compatibility | Eliminates large waste lines | Significant reduction in water consumption |

| Remote Monitoring | Identifies leaks or tampering instantly | Predictive maintenance reduces cell downtime |

4. Material Science: The Superiority of Stainless Steel

When choosing between materials for a prison toilet sink combo, stainless steel is the undisputed winner for institutional use.

Grade 304 vs. Grade 316 Stainless Steel

- Type 304: This is the standard for most prison toilet sink combo units. It offers excellent corrosion resistance and durability.

- Type 316: In facilities located near the coast or those using highly aggressive cleaning chemicals, Type 316 is often specified. Its higher molybdenum content provides superior resistance to chloride-induced pitting and corrosion.

Non-Porous Surfaces and Infection Control

In high-density environments, the spread of infectious diseases (such as MRSA or seasonal flu) is a constant threat. The non-porous surface of a stainless steel prison toilet sink combo is naturally resistant to the colonization of bacteria and viruses. Unlike porcelain, which can develop microscopic cracks (crazing) that harbor pathogens, cleaning crews can sanitize stainless steel with industrial-grade disinfectants without degrading the material.

Immediate Hygiene and Handwashing

Psychologically and practically, attaching the sink directly to the toilet encourages inmates to practice better hand hygiene. In a prison toilet sink combo, the proximity of the lavatory to the water closet ensures that inmates are more likely to wash their hands immediately after use, reducing the overall bio-burden within the cell and the facility at large.

5. Economic Logic: Analyzing the Total Cost of Ownership (TCO)

While the initial purchase price of a stainless steel prison toilet sink combo is higher than a commercial porcelain set, the long-term economic argument is overwhelming.

Reduced Installation Complexity

Installing two separate fixtures requires two sets of wall penetrations, two sets of mounting brackets, and twice the labor for plumbing connections. A prison toilet sink combo simplifies this process:

- Single Unit Handling: Only one fixture needs to be transported and positioned in the cell.

- Consolidated Plumbing: The waste lines for the sink and toilet can often be merged within the unit, requiring only one main connection to the waste stack in the chase.

- Reduced Labor Hours: Contractors spend significantly less time per cell, which is a major factor in large-scale construction projects.

Durability and Replacement Cycles

A porcelain toilet in a maximum-security prison has a remarkably short lifespan—often less than five years before inmates crack or intentionally damage the fixture. In contrast, a stainless steel prison toilet sink combo is a 30-year asset.

Industry leaders like Xinhe focus on this longevity, ensuring their stainless steel toilet models withstand the daily stress of high-traffic detention environments.

6. Regulatory Compliance and Universal Design

Modern correctional facilities increasingly prioritize international human rights and accessibility standards. This has influenced the evolution of the prison toilet sink combo.

ADA Compliance and Handicap Accessibility

A certain percentage of cells in any new facility must be ADA-compliant. Manufacturers have developed specialized handicap-accessible prison toilet sink combo units that feature:

- Extended Toilets: To allow for easier transfer from a wheelchair.

- Lowered Sinks: To provide proper knee clearance and reach for a seated inmate.

- Integrated Grab Bars: Reinforced mounting points that allow for the installation of security-grade grab bars.

International Standards

Whether it is the European Committee for the Prevention of Torture (CPT) or the ACA in the United States, there is a global consensus that detention fixtures must provide dignity while maintaining safety. The smooth, “normative” look of modern stainless steel helps create a more humane environment without sacrificing the unbreakable nature of the fixture.

7. The Psychology of the Cell Environment

There is a growing school of thought that “normative” design—making a cell look more like a standard room—can reduce inmate stress and lower rates of violence.

While the prison toilet sink combo is inherently institutional, modern finishes can soften the aesthetic. Satin-finish stainless steel reflects light better than old, brushed finishes, making a small cell feel brighter. Furthermore, by keeping the cell clutter-free (eliminating extra pipes and separate fixtures), the environment feels more orderly, which has a calming effect on the population.

8. Installation Best Practices for Contractors

For the B2B sector, the success of a project often depends on the ease of installation. When specifying a prison toilet sink combo, contractors should consider the following:

- Wall Thickness: Facilities must order units with a “sleeve” or mounting plate that matches the specific thickness of the reinforced concrete wall.

- Template Precision: Because these units are heavy and bolted through the wall, the layout of the plumbing penetrations must be exact. Many manufacturers provide laser-cut templates to ensure a perfect fit.

- Sealant Application: Using a high-quality, non-pick security sealant around the perimeter of the unit is essential to prevent the accumulation of moisture and the hiding of small contraband.

Conclusion

The prison toilet sink combo is much more than a plumbing fixture; it is a critical safety barrier, a space-saving tool, and a long-term financial asset. By integrating the lavatory and water closet into a single, indestructible unit, facilities can ensure maximum security, optimize operational efficiency, and maintain the highest standards of hygiene.

Looking for high-performance detention solutions? Consult with an industry specialist to find the ideal configuration for your facility’s specific security requirements.