Why Choose Stainless Steel Urinal Trough for High-Traffic Spaces

Busy public restrooms never sleep. Crowds rush through airports, stadiums, schools, and malls every day, putting enormous pressure on every fixture. When a urinal fails, it doesn’t just create inconvenience—it costs money, frustrates users, and damages reputation. A stainless steel urinal trough quietly solves these problems with exceptional strength, hygiene, and long-term economy.

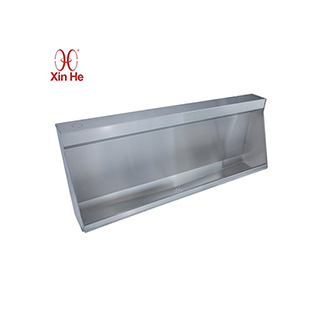

Facility managers, project buyers, wholesalers, contractors, and importers constantly weigh the same trade-offs: upfront cost versus lifetime performance, appearance versus real-world toughness, quick fixes versus lasting solutions. For high-traffic men’s rooms, many professionals find that a customized 304/316 stainless steel wall mounted public trough urinal provides the ideal balance of durability and easy installation. This article explains exactly why stainless steel urinal trough systems have become the professional choice for demanding environments.

Superior Durability: Built for High-Traffic Environments

High-traffic restrooms are unforgiving test labs. Fixtures face constant use, accidental kicks, heavy cleaning tools, harsh chemicals, and occasional deliberate abuse. Only the toughest materials survive long enough to deliver good return on investment.

Corrosion and Impact Resistance

The backbone of any quality stainless steel urinal trough is the grade of steel used — most commonly AISI 304 for standard indoor applications and AISI 316 when exposure to chlorides, coastal air, or aggressive cleaning agents is expected. This same heavy-duty construction is why prison toilet manufacturers boost safety in jails by using stainless steel; it is virtually impossible to shatter or compromise.

AISI 304 contains 18% chromium and 8% nickel, creating a self-healing passive oxide layer that dramatically slows corrosion — think of it as built-in armor that repairs itself when scratched. AISI 316 adds 2–3% molybdenum, making it significantly more resistant to pitting and crevice corrosion in challenging environments.

Compare this performance to alternatives:

- Ceramic — beautiful when new, but brittle; one solid impact can crack or chip it

- Plastic/composite — lightweight and cheap initially, but warps, discolors, and degrades under UV, chemicals, and heat

- Powder-coated steel — good appearance at first, but once the coating chips (which happens quickly in public use), rust appears rapidly

From a procurement perspective, choosing a corrosion-resistant CE certified stainless steel floor standing urinal for public restrooms translates directly to fewer warranty claims and dramatically lower total ownership cost.

Industry field experience consistently shows stainless steel urinal trough systems lasting 20–35 years in heavy commercial use, compared to 8–15 years for most competing materials.

Long-Term Performance in Demanding Public Spaces

Real-world examples illustrate the difference:

- Major international airports (LAX, JFK, Heathrow) use stainless steel urinal troughs because they must remain operational 24/7 with minimal intervention

- Professional sports stadiums survive game-day surges of 50,000+ visitors without structural failure

- Large school districts report 60–80% reduction in fixture replacement frequency after switching to stainless steel

- Hospitals rely on stainless steel because it withstands aggressive daily disinfection protocols without surface degradation

In B2B terms, uptime equals revenue protection. A single out-of-service restroom bank in a busy terminal or arena can create visible queues, negative social media posts, and measurable customer dissatisfaction. Traders and wholesalers who position long-lasting stainless steel urinal systems gain significant competitive advantage through lower complaint rates and stronger end-user references.

Manufacturing Quality That Makes the Difference

Not all stainless steel troughs are equal. Premium manufacturers reinforce critical stress points, use full-length back bracing, employ seamless TIG welding, deburr and polish all edges, and pressure-test every unit.

These seemingly small details create big outcomes:

- Much higher resistance to deformation under weight or impact

- Zero leak paths at weld joints

- Safer, cleaner edges that reduce injury risk and simplify cleaning

- Professional appearance that ages gracefully instead of looking tired after a few years

For contractors, better fabrication quality means faster, cleaner installs with fewer call-backs. For importers and distributors, it means fewer quality rejections and stronger brand reputation.

Hygiene and Easy Maintenance: Critical for Public Health

Public restrooms are among the highest-risk environments for surface-mediated germ transmission. A stainless steel urinal trough offers measurable hygiene advantages that directly support public health goals.

Non-Porous Surface and Bacterial Resistance

Stainless steel is naturally non-porous at the microscopic level — unlike glazed ceramic (which develops micro-cracks over time) or plastic (which can absorb organic compounds).

Multiple peer-reviewed studies have demonstrated that smooth stainless steel surfaces reduce bacterial adhesion by 70–95% compared to other common restroom materials. This makes routine cleaning dramatically more effective.

In healthcare facilities, schools, and food-related venues, this difference can translate into lower infection transmission risk and better compliance with health authority guidelines.

Streamlined Daily Cleaning Process

Maintenance teams appreciate how quickly a stainless steel urinal trough can be returned to sanitary condition:

- Smooth, seamless surfaces release soil easily

- No grout lines to trap residue

- Compatible with virtually all commercial disinfectants (including bleach, quaternary ammonium, hydrogen peroxide, and alcohol-based formulas)

- Resists staining from urine, hard water, and cleaning chemicals

Typical high-traffic cleaning protocol: quick daily wipe-down with neutral cleaner or disinfectant — usually 30–60 seconds per trough versus 3–5 minutes for multi-piece ceramic systems with grout and joints.

Labor savings accumulate rapidly across dozens or hundreds of units.

Compliance with Modern Health Standards

Current-generation stainless steel urinal troughs routinely meet or exceed:

- EHEDG hygienic design guidelines

- NSF/ANSI 51 food equipment materials standards

- Various national public health plumbing codes

Full material certification packages are available from serious manufacturers, greatly simplifying specification approval and inspection processes for contractors and facility owners.

Life-Cycle Cost Efficiency: A B2B Perspective

When professionals calculate total cost of ownership, stainless steel urinal troughs almost always win in high-traffic applications.

Lower Maintenance & Replacement Frequency

Realistic 10–15 year maintenance cost comparison (mid-sized commercial facility, 20 units):

- Ceramic systems: $18,000–$32,000 (frequent part replacement, grout repair, labor)

- Plastic/composite: $14,000–$26,000 (warping, discoloration, full unit replacement)

- Stainless steel: $4,500–$9,000 (mostly cleaning supplies + occasional minor hardware)

The difference often covers the higher initial purchase price within 4–7 years.

Water & Utility Savings Potential

Many modern stainless steel urinal trough designs incorporate:

- Low-flow or waterless flush options

- Integrated flush valves with automatic detection

- Optimized drain slopes for better evacuation with less water

These features can reduce water consumption by 50–100% compared to traditional single urinals, creating significant utility cost savings plus environmental compliance benefits.

Value-Added Procurement Advantages

Serious manufacturers frequently offer:

- Tiered volume pricing for project quantities

- Project-specific quotations with fixed lead times

- Customization without prohibitive tooling charges

- Extended warranty programs on premium grades

These elements transform a simple product purchase into a strategic partnership that protects margins and project timelines.

Modern Design and Customization Options

Today’s stainless steel urinal trough is far from industrial-only. Contemporary finishes and customization options allow seamless integration into almost any architectural environment.

Aesthetic Choices That Matter

Available surface finishes include:

- Brushed/satin — hides fingerprints and water spots best

- Mirror/polished — creates a premium, upscale appearance

- Anti-fingerprint coatings — maintains clean look longer in heavy-touch areas

- Bead-blasted/matte — contemporary low-reflection look

These options let designers match modern, industrial, luxury, or minimalist restroom aesthetics.

Tailored Solutions for Unique Projects

Serious manufacturers provide genuine OEM/ODM services:

- Custom lengths from 36″ to 144″+ in 6″ increments

- Variable depth and height for ADA compliance or special architecture

- Multiple drain locations and configurations

- Integrated sensor flush systems, privacy screens, or dividers

- Special mounting options (wall-hung, floor-mounted, semi-recessed)

Lead times for custom work typically range from 4–8 weeks depending on complexity — much faster than custom ceramic solutions.

Conclusion

For high-traffic public and commercial restrooms, a properly specified stainless steel urinal trough delivers the best combination of:

- Exceptional durability and vandalism resistance

- Superior hygiene and cleaning efficiency

- Lowest long-term ownership cost

- Modern aesthetics with extensive customization possibilities

Xinhe specializes in manufacturing high-quality stainless steel sanitary fixtures, offering project-specific solutions backed by strong technical support.

Request our latest product catalog. Schedule a technical consultation for your upcoming project. Contact us today for a customized quotation.

FAQs

Q: Is a stainless steel urinal trough more expensive than individual urinals?

A: Initially, yes. However, when you factor in the reduced number of plumbing connections needed (one drain vs. many) and the 30-year lifespan, the trough is significantly more cost-effective.

Q: How do you prevent the “industrial” smell in a trough?

A: Odors are caused by poor drainage or porous surfaces. Our troughs feature a steep internal pitch for rapid drainage and a non-porous finish that prevents urine from soaking into the material.

Q: Can these be customized for specific room layouts?

A: Yes. We specialize in OEM/ODM services, allowing for L-shaped troughs, specific lengths, and custom splashback heights.