Why Scrub Sinks Are Standard in Medical Settings

If you’re working in a busy medical clinic, hospital, or surgical center, you’ve probably noticed how scrub sinks are a non-negotiable part of the setup. These practical fixtures go beyond just being a place to wash up—they’re engineered to uphold strict hygiene standards in environments where germs can spread fast, whether from patients in a doctor’s office or during intricate procedures in an operating room. By featuring things like touch-free controls and robust materials, scrub sinks help teams maintain cleanliness without skipping a beat, drawing from trusted guidelines like those from the CDC and WHO to keep everyone safer.

Unique Infection Risks Across Medical Environments

In any healthcare space, from a local clinic to a full-scale hospital, infection risks lurk around every corner due to the constant flow of people and potential pathogens. It’s like managing a high-stakes kitchen where one wrong move could spoil the whole batch—scrub sinks step in as that essential tool to keep things clean and controlled, adapting to the specific challenges of each setting.

How Pathogens Spread in Healthcare Spaces

Germs travel through contact, airborne droplets, or shared surfaces, and in medical settings, this can happen during routine check-ups or emergencies. For instance, in a surgical suite, residues from one procedure might carry over if hands aren’t properly scrubbed, leading to complications. Studies indicate that poor hand hygiene links to about 40% of healthcare-associated infections across facilities, making dedicated hand washing sinks or utility sinks vital—far more effective than a simple mop sink for clinical demands.

Challenges with Infectious Diseases in Varied Settings

Infectious diseases don’t discriminate between human clinics and specialized ones; think of how flu viruses or resistant bacteria like MRSA can jump around in waiting rooms or ORs. Outdoor sink stations might handle quick rinses in field medicine, but core scrub sinks ensure thorough decontamination. This setup helps mitigate risks, fostering a welcoming environment where patients feel secure.

Factors That Heighten Risks in Daily Operations

Busy hallways, equipment handling, and environmental variables like humidity can amplify contamination. A splash from a shallow basin sink could scatter microbes onto nearby areas, but deep kitchen sinks in scrub designs contain it all. Stainless utility sinks add resilience, turning potential hazards into manageable routines for your team.

CDC data shows that strong hand hygiene protocols, supported by proper scrub sinks, can reduce infection rates by 30-50% in medical practices.

Key Functional Needs for Scrub Sinks

Selecting a scrub sink is about fitting it seamlessly into your workflow, much like choosing the right gear for a long shift—it needs to be reliable, intuitive, and tailored to the job. Guidelines from bodies like OSHA highlight designs that minimize errors while maximizing ease, so your staff can prioritize patient care.

Hands-Free Operation and Controls

No one wants to re-contaminate clean hands by grabbing a faucet handle. Knee or foot pedal sinks offer a simple fix with hands-free activation, ideal for fast-paced surgical or clinic areas. Unlike basic commercial sink faucets, these include smart sensors in prep sinks, streamlining transitions during back-to-back consultations.

- Choose knee or foot controls for effortless hygiene

- Add anti-scald tech in mop sink faucets to avoid mishaps

- Integrate with drains in 3 compartment sinks for heavy-duty use

Basin Configurations to Curb Splashes

The basin should act like a secure container, deep enough to trap water and prevent airborne spread. Utility sink dimensions of 20-30 inches outperform compact bar sinks small, especially in surgical contexts where fluids are plentiful—unlike shallower laundry sinks that risk overflow.

Comfort-Focused Ergonomics for Teams

Awkward postures can lead to fatigue, so OSHA recommends 34-36 inch sink heights to promote better form during extended scrubs. Ada compliant sinks ensure inclusivity, and wall mount sinks optimize tight spaces in outpatient clinics. This approach keeps everyone comfortable and focused.

Material Choices from a Practical Angle

Materials matter because they need to withstand the daily grind while staying spotless, similar to picking durable cookware that cleans up easily. Stainless steel leads the pack for its balance of strength and sanitation, but the grade you choose depends on your facility’s exposure to cleaners and wear.

Properties That Fight Corrosion

304 stainless provides dependable protection against everyday disinfectants, creating a barrier that self-heals. For harsher conditions, like in emergency rooms with frequent chemical use, 316’s added elements boost resistance. This suits stainless laundry sinks in moist areas, warding off degradation that could invite germs.

Strength Through Thickness and Build

Opting for 16-gauge over 18-gauge can extend life by up to 40% in active environments. It’s akin to reinforcing a bridge for heavy traffic; in hospitals, this durability keeps commercial kitchen sinks going strong amid constant activity.

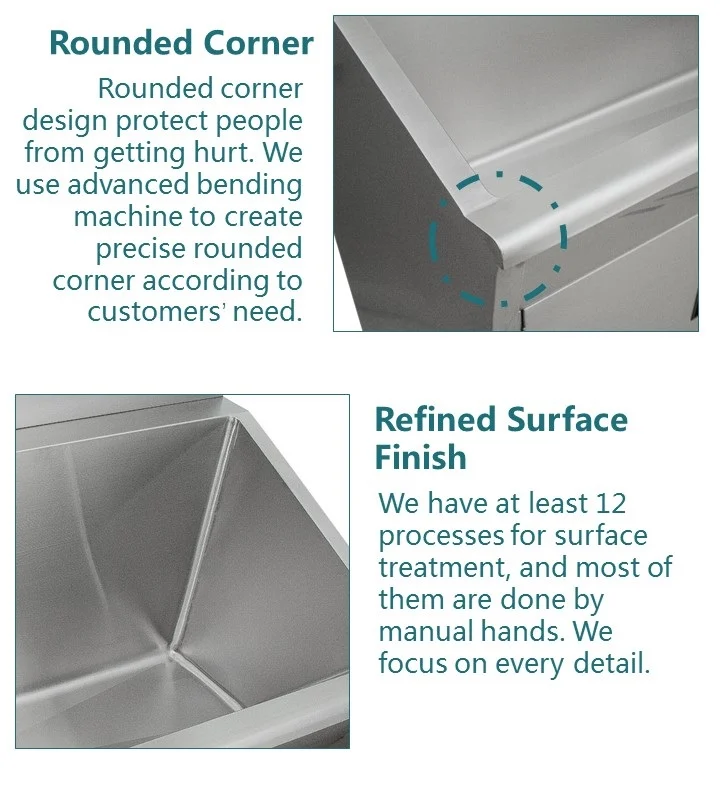

Designs Prioritizing Cleanliness

Rounded corners and seamless joints in bowl sinks eliminate nooks for bacteria, while textured finishes on drop in sinks resist marks. Extras like sink basket strainers simplify upkeep, meeting criteria for industrial sinks in sterile zones.

| Material Option | Core Advantages | Best Fit Scenarios | Longevity Boost |

|---|---|---|---|

| 304 Stainless | Cost-effective, reliable rust resistance | Routine clinics, general scrub sinks | Steady for standard ops |

| 316 Stainless | Enhanced defense against chemicals | Surgical suites, outdoor sink stations | 40% extra in tough spots |

Smart Design Tips and Mistakes to Sidestep

Designing with scrub sinks in mind is about practicality—positioning them where they enhance flow without creating bottlenecks, avoiding pitfalls that could undermine your efforts.

Strategies for Effective Placement

Locate sinks strategically near entry points or procedure areas but away from high-contamination zones. Portable sink stations add versatility for mobile units. A hospital upgrade with centralized handwash sinks cut incidents by 25%, proving thoughtful planning works.

- Set near ORs but isolated to contain risks

- Multiply in larger facilities for convenience

- Use freestanding utility sinks for flexible layouts

Steering Clear of Typical Oversights

Shallow shop sinks invite splashes, and studies tie bad positioning to 20% of hygiene issues. Neglecting touch-free in service sinks is common; focus on depth and automation instead.

Insights from Real Scenarios

One surgical center installed 316 stainless ada compliant sinks, dropping infections 35% yearly. Another fixed spread from shared commercial bathroom sinks by creating dedicated areas.

Standards and Compliance in Healthcare

Compliance builds a foundation of reliability, turning guidelines from AAVMC, OSHA, and others into actionable steps for safer spaces.

AAVMC Guidelines for Facility Layouts

They advocate smooth constructions and smart placements to bolster control in diverse medical contexts.

OSHA’s Take on Safety and Comfort

Emphasizing ergonomic elements to reduce strains, relevant in all healthcare setups.

Hygiene Directives from AVMA, CDC, and Beyond

AVMA focuses on dedicated scrubbing, while CDC integrates alternatives for comprehensive strategies.

Wrapping things up, these elements guide you toward scrub sinks that truly support your medical environment. For tailored solutions in stainless steel products, consider exploring options at https://www.xstainless.com/.